Measurement While Drilling (MWD) and Logging While Drilling (LWD) Drilling Efficiency

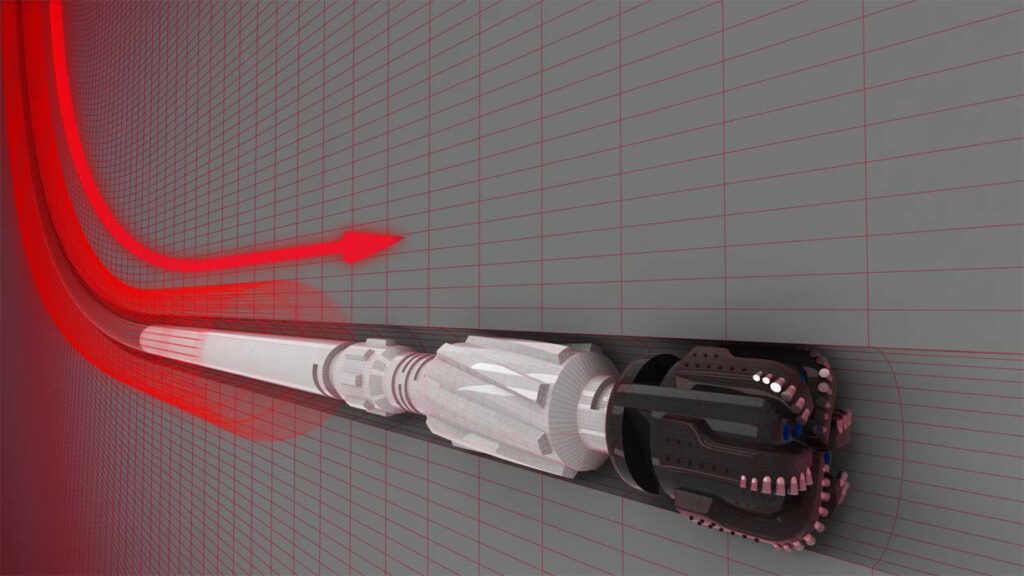

Oil and gas deposits are present in the strata of the Earth’s crust and these hydrocarbon resources are accessed by drilling vertical and horizontal wells. In order to minimize risks and optimize results a better understanding of the strata around the proposed target or “payzone” is required. Direct observation of these sub surface formations is not possible, so, various tools are lowered into the wellbore to map the path of the well and to record the physical properties of rock surrounding the wellbore.

Measurement While Drilling (MWD)

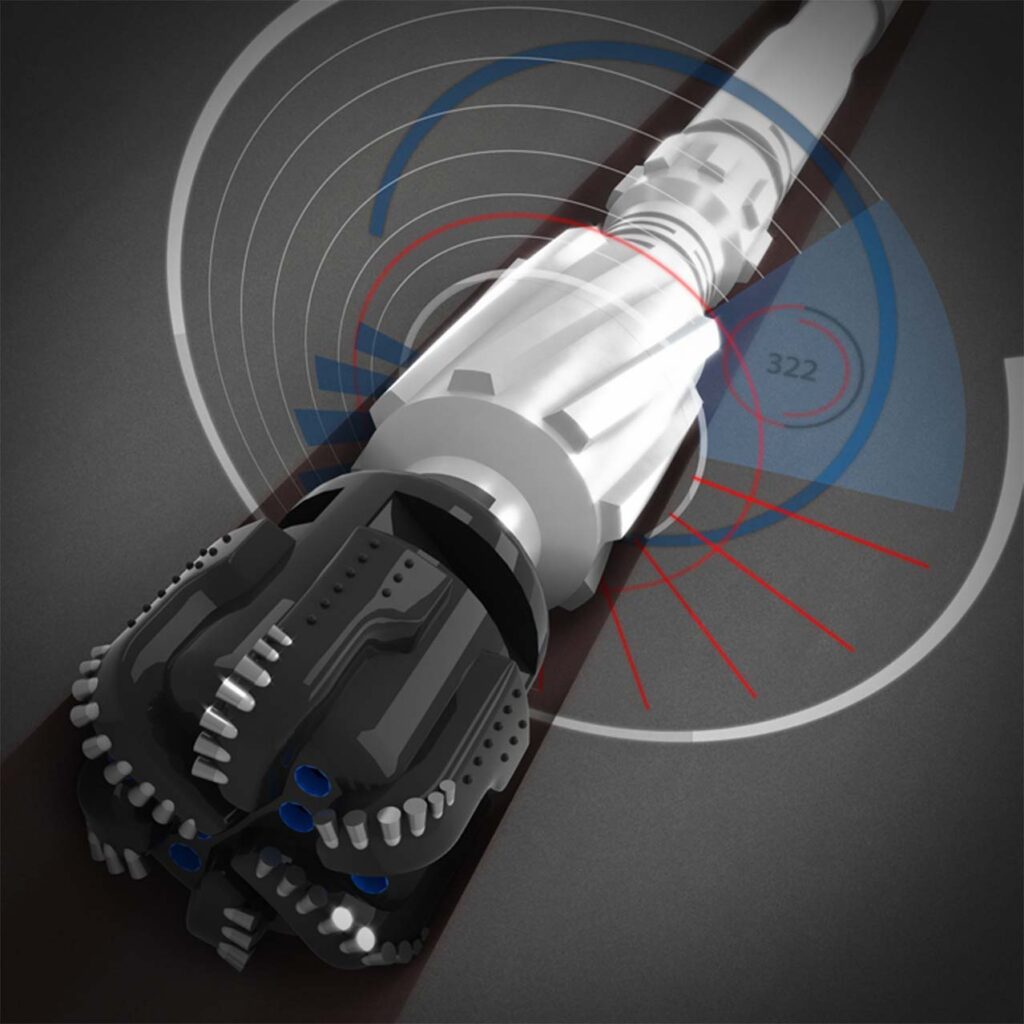

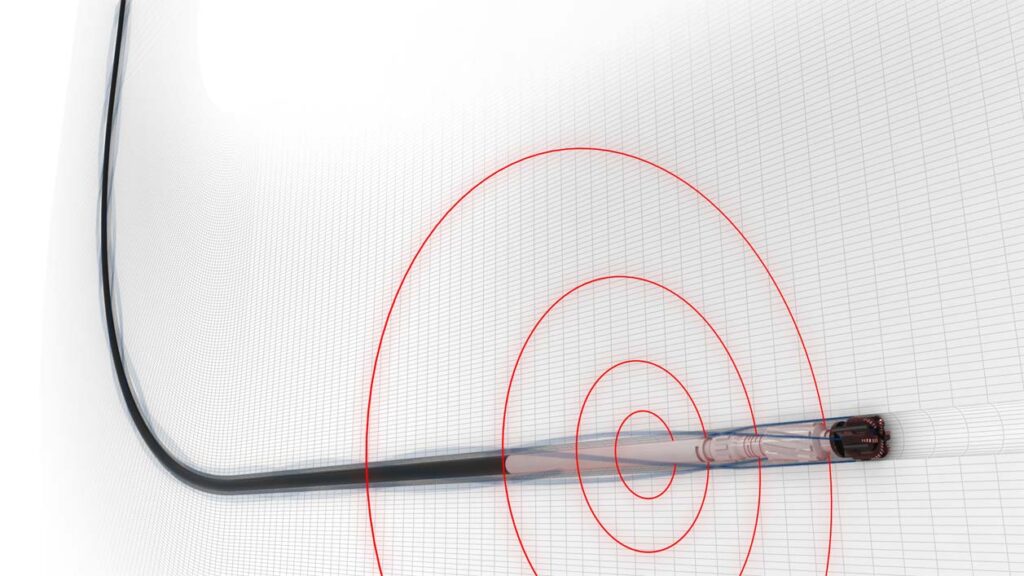

Measurement While Drilling is the system by which the wellbore trajectory is logged and monitored continuously during the drilling process. The use of MWD has increased with the development of the unconventional exploration sector as it enables the drilling of the wellbore in the planned direction so targeted reservoir formations can be tapped accurately. MWD tools are used as part of the Bottom Hole Assembly (BHA) and powered either by lithium batteries or a turbine that produces electric power by harnessing the kinetic energy of drilling fluid.

MWD Procedure And Data Set

Measurement while drilling tools are run into the wellbore as a part of the drill string to measure the direction of the wellbore with respect to the north (Magnetic/Grid/True), the inclination of the wellbore, the true vertical depth of the well and dogleg severity. This information acquired by MWD tools is either stored in solid-state memory or sent to the recording station present at wellhead via wireless mode, i.e., mud pulse telemetry or electromagnetic telemetry. This deviation data is very useful for the drilling team to determine the borehole position, directional drilling control, and helps to keep the well in the right direction. MWD tools are designed to withstand downhole temperature and pressure conditions while also being capable of withstanding the vibrations and shocks produced during drilling. The deviation data set plays a vital role while designing and positioning the wells to avoid well collision.

Logging While Drilling

It is important to study rock formation properties surrounding the wellbore to mark the hydrocarbon producing zone and to visualize a better understanding of the subsurface. Conventionally, wireline logging is used whereby the logging tools are run into the well using a specialized cable. These tools record the physical properties of rocks against depth and send them to the surface logging unit where these values are processed and displayed in the form of a log. Logging while drilling is an effective modern technique in which the physical properties of the rocks are recorded during drilling offering greater time saving as there is no need to stop drilling and/or removal of the drill string from the well. LWD has many advantages as it delivers data in real time to operators…saving time and money.

LWD Procedure and Data Set

The most common LWD measurement is gamma ray followed by resistivity. Occasionally more exotic logging tools are required such as Sonic, Neutron Porosity, Azimuthal Density and PEF logs. These LWD logging tools are run as a part of the drilling assembly and in some configurations the data is transmitted to surface where they are processed and displayed as a log. It is crucial to run these logs in the well because they give the information about the reservoir quality by giving an estimate of its shale content, porosity and saturation of hydrocarbons. These logging results are acquired and interpreted carefully because they decide the future of the well, i.e., it will be productive, uneconomical or dry. Because logging has great importance in exploration and production of hydrocarbons it is also used to maintain data accuracy in highly deviated wells where wireline logging is not applicable.

MWD and LWD Advantages

Measurement while drilling and logging while drilling are considered some of the most important technologies for the drilling of deviated and horizontal wells. These services optimize the well path and trajectory to the subsurface target. Without MWD/LWD it is very difficult to tap subsurface targets especially in the case of deviated wells. When weak lithology or any fault zone are encountered the drill bit moves along the weak zone that also results in the deviation of the well. So, measurement while drilling monitors the well path to avoid such unwanted deviations. In high dogleg severity wellbores, conventional logging like wireline logging cannot be used because the logging tool cannot be run easily at high deviations. Logging while drilling is adopted to log the reservoir and measure petrophysical properties of formations in a manner that is also a time saving and money-saving practice. Even further, no drill string tripping or additional units are required for logging while drilling.

Conclusion

Drilling complexities are increased as the upstream sector searches for deeper and unconventional oil and gas reserves. Because of these complexities more advanced tools are introduced to maintain data accuracy and quality. These tools also aid in the acquisition of data in tough hole conditions. Measurement while drilling and logging while drilling are among such techniques. Measurement while drilling ensures the right well path direction to reach the desired subsurface target. On the other hand, logging while drilling provides the subsurface information like lithology, porosity, hydrocarbon saturation and in some cases permeability and orientation of subsurface formations. So, these modern techniques have greatly reduced the risks associated with exploration and production of hydrocarbon.